I. Design Stipulations

- Characteristic compressive strength of concrete required at the site at 28 days (fck)=25 MPa

- Maximum size of aggregate = 20 mm

- Shape of coarse aggregate = Angular (Crushed)

- Degree of workability = 100 mm for RCC as per provision made in relevant Indian Standard.

- Degree of quality control = good

- Type of exposure = Moderate

II. Test Data for Materials

- Cement

- Cement used: OPC

- Initial setting time of cement = 30 minutes

- Final setting time of cement = 590 minutes

- Specific gravity of cement = 3.15

- Fineness value of cement = 4 % (As per IS 4031 part 1)

- Soundness of cement = 6 mm (As per IS 4031 part 3)

- Standard Consistency = 32 %

- Coarse Aggregate

- Specific gravity of coarse aggregate = 2.72 (IS 2386, part 3)

- Water absorption of coarse aggregate = 0.7%

- Free (surface) moisture percent on coarse aggregate = nil

- Fine Aggregate

- Specific gravity of fine aggregate = 2.67 (IS 2386, part 3)

- Water absorption = 1.5 %

- Free (surface) moisture percent on fine aggregate = nil

- Admixture

- Admixture Used: Superplasticizer (Water Reducer)

III. Sieve Analysis of Aggregate

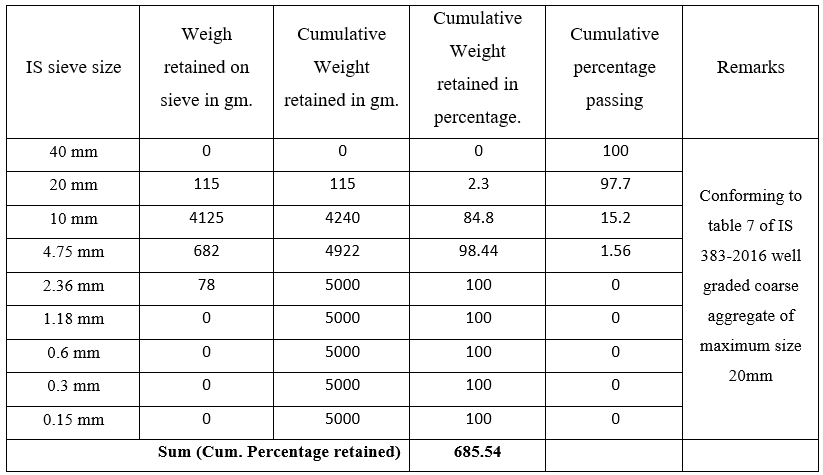

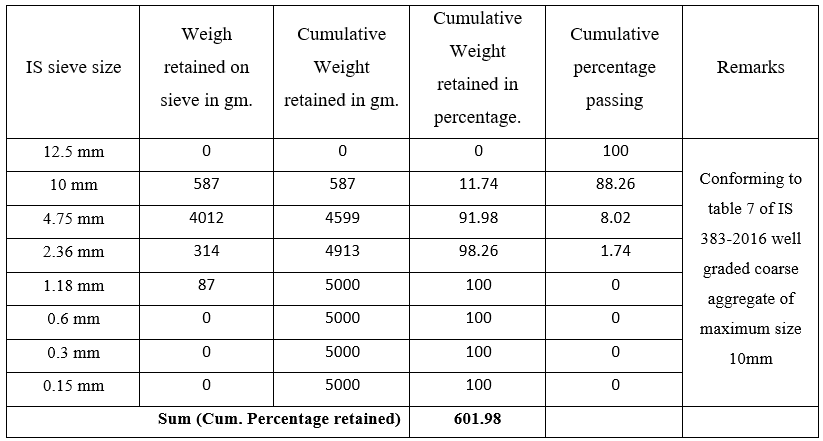

- Coarse aggregate (20mm Size and Down)

- 5 kg has been taken for sieve analysis. The result is tabulated as below:

- Coarse aggregate (20mm Size and Down)

- 5 kg has been taken for sieve analysis. The result is tabulated as below:

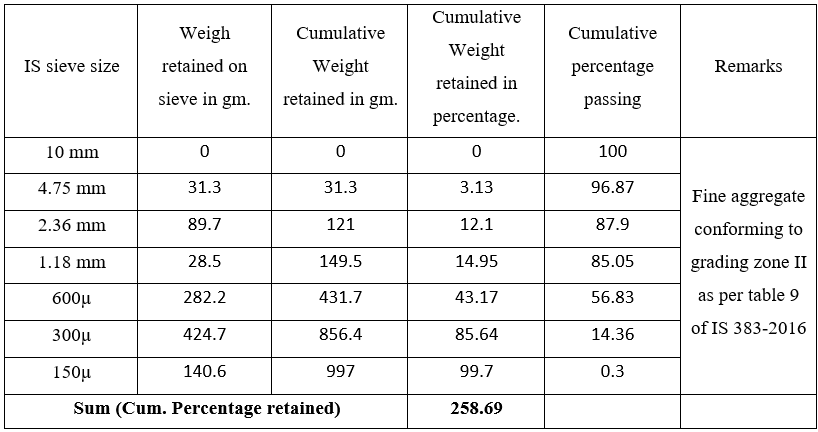

- Fine aggregate

- 1 kg has been taken for sieve analysis. The result is tabulated as below:

M25 design of mix is to be carried out as per IS 10262:2019.

- Mix Design Calculations

- Target mean strength of concrete: (fm) = fck + k × s

- Where fck= 25 MPa (given)

- k = 1.65

- s = 4 (from table 2 of IS 10262:2019)

- fm = 25 + 1.65 x 4

- = 31.60 MPa

- Approximate Air Content

- As per IS: 10262-2019, From Table 3, the approximate amount of entrapped air to be expected in normal (non-air-entrained) concrete is 1.0 percent for 20 mm nominal maximum size of aggregate.

- Selection of Water Cement Ratio (W/C):

- For moderate exposure, maximum water cement ration (as per table 5 of IS 456-2000) = 0.5

- Based on experience adopting W/C as 0.45.

- Selection of Water content:

- Using Table 4 of IS 10262-2019:

- Maximum water content = 186 kg (20 mm maximum aggregate size)

- Estimated water content for 100 mm slump = 186 + (6/100) × 186 = 197.16 lit.

- As Superplasticizer is used, the water content may be reduced by 23 % (as per experience).

- Hence, water content = 151.81 kg.

- Adopting 152 kg.

- Determination of cement content:

- W/C ratio = 0.45

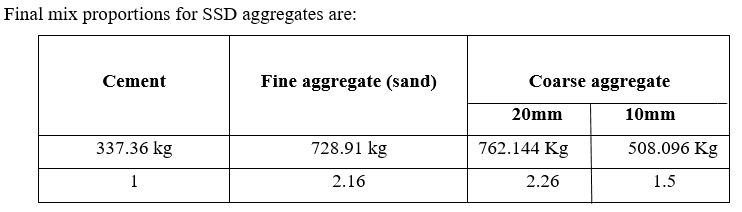

- Cement content = 151.81/0.45 = 337.36 kg per cum of fresh concrete

- Minimum cement content for moderate exposure in case of M25 (as per Table 5 of IS:456-2000) = 300 kg/m3.

- Therefore, adopting 337.36 kg of cement.

- Determination of proportion of aggregate:

- From Table-5 of IS 10262-20019, the volume of coarse aggregate per unit volume of total aggregate for Zone II corresponding to 20 mm maximum size aggregate & w/c 0.50 is equal to 0.62.

- In the present case water cement ratio is 0.45.

- As the water cement ratio is lower by 0.05, the proportion of volume of coarse aggregate is increased by 0.01.

- Therefore, corrected proportion of volume of coarse aggregate for water cement ratio of 0.45 = 0.63.

- Volume of fine aggregate = 1-0.63 = 0.37

- Mix Calculation:

- The mix calculation per unit volume of concrete shall be as follows:

- Volume of concrete = 1 m3

- Volume of cement = (mass of cement/specific gravity of cement) × (1/1000)

- = 0.107 m3

- Volume of water = (mass of water/specific gravity of water) × (1/1000)

- = 0.152 m3

- Volume of Chemical admixture = 0.003

- Volume of all aggregate = 1- (0.107 + 0.152+0.003) = 0.738 m3

- Volume of coarse aggregate = 0.465 m3

- Volume of fine aggregate = 0.273 m3

- Mass of coarse aggregate = 0.465 × 2.72 × 1000 = 1270.24 kg

- Mass of fine aggregate = 0.273 × 2.67 × 1000 = 728.91 kg

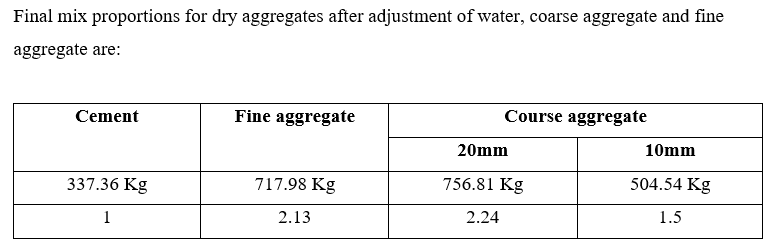

Coarse aggregate is further divided in to two parts, 60% of 20 mm size and 40% of 10 mm size aggregate.

- Mass of 10 mm coarse aggregate = 508.096 kg

- Mass of 20 mm coarse aggregate = 762.144 kg

- Adjustment of Water, Fine Aggregate and Coarse Aggregate:

- Water absorption of coarse aggregate = 0.7 %

- Water absorption of fine aggregate = 1.5 %

- Water correction =

- Total water = 152 + 19.82 = 171.82 kg

- Coarse aggregate = 1270.24 – 8.89 = 1261.35 kg

- Fine aggregate = 728.91 – 10.93 = 717.98 kg