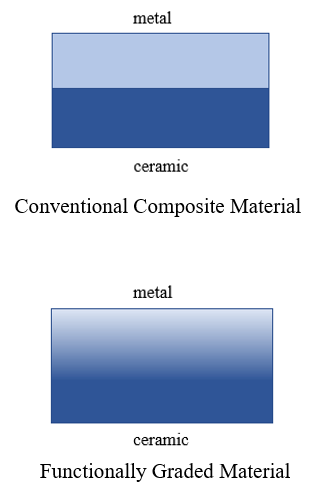

The functionally graded materials (FGMs) are advanced composite material which differs from usual composites in the organization of their material constituents, giving a smooth variation on their macroscopic structure in the desired direction. FGMs have taken major attention in various engineering applications and in manufacturing industries viz. civil engineering, aerospace, nuclear reactor, automobile, aircraft, space vehicles, biomedical and steel industries. The difference in material variation is shown in figure below.

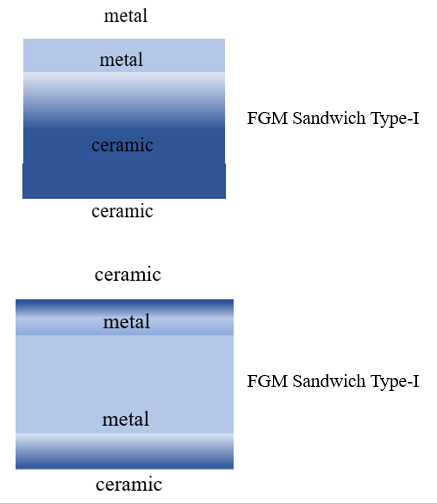

Due to the large jump of material properties at the layer interfaces, the problem of delamination is generally observed in conventional composite structures. The concept of FGM is also employed in sandwich structures to overcome this problem. The FGM sandwich are modelled by two kinds of approaches. In the first type, the core part is designated by the FGM; while the top and bottom layers are rich in metal component and ceramic component, thus leading to an FGM profile at the top and bottom layers. In the second type, the top and bottom layers are defined by FGM and hence the core portion is defined by metal components. The representation of both type of functionally graded sandwich materials are shown below.

Advantages of Functionally Graded Materials Over Conventional Composite Materials

•Provide multi-functionality

•Provide ability to control deformation, dynamic response, corrosion, etc. and ability to design for different complex environments

•Provide ability to remove stress concentrations

•Provide opportunities to take the benefits of different material systems [e.g. ceramics and metals such resistance to oxidation (rust), toughness etc.]